TheStaticTurtle

TheStaticTurtleSome of you may know that you can use yubikey's as a gpg smart card for message encryption / ssh login however starting at $45 for a compatible one I didn't really like that, so I searched a bit to make a DIY one.

Turns out, there is a project by danman creating such token with a St link V2 (the stm32/8 programmer) after looking a bit I found out that there is the gnuk project that implements just that on a stm32f103.

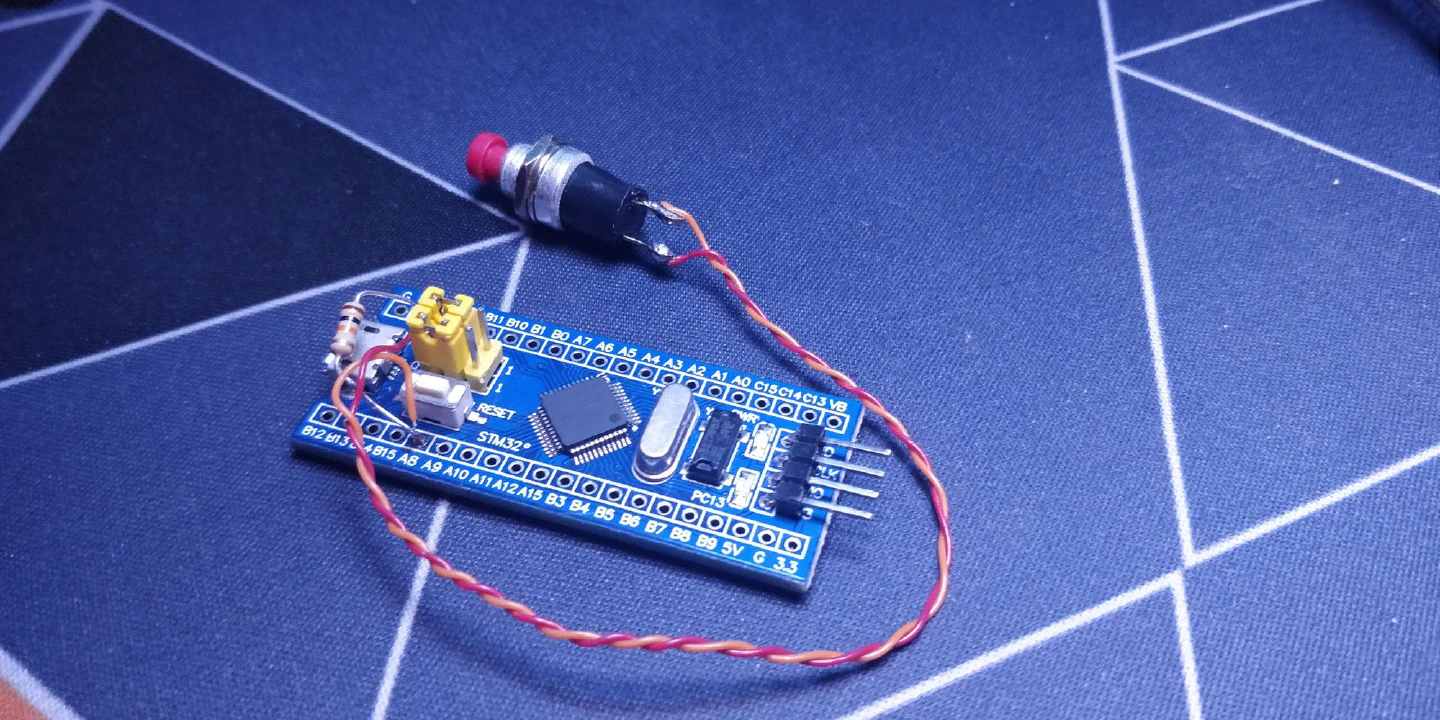

I, next found that there is another gpg key called the Nitro Key which is cheaper but still a bit pricey. As I already had some Blue pills (stm32f103 devboard) lying around I decided to test it.

I started by finding the source code of gnuk (and the sub module chopstx) which was more difficult than I thought (Some git services were shut down), upon finding the source on GitLab I cloned it on my GitHub (https://github.com/TheStaticTurtle/gnukhttps://github.com/TheStaticTurtle/chopstx/).

I named my project TurtleAuth, so I started by just using the same config as the ST_DONGLE target since I don't plan on changing the MCU and the officials ones are based on the stm32f103c8 (clones are often the stm32f101 which doesn't officially have "USB capabilities" but can be used anyway somehow). I proceed by creating my own board definition (chopstx/board/turtle-auth.h) and adding / changing configuration like the led pin which I set to PA13 (On board led on the bluepill) and configuring a button on PA8 in pull up

1/*

2 * Port A setup.

3 * PA11 - Push Pull output 10MHz 0 default (until USB enabled) (USBDM)

4 * PA12 - Push Pull output 10MHz 0 default (until USB enabled) (USBDP)

5 *

6 * Port C setup.

7 * PC13 - Push pull output 50MHz (LED 1:ON 0:OFF)

8 * ------------------------ Default

9 * PAx - input with pull-up

10 * PCx - input with pull-up

11 */

12#define VAL_GPIO_USB_ODR 0xFFFFE6FF

13#define VAL_GPIO_USB_CRL 0x88888888 /* PA7...PA0 */

14#define VAL_GPIO_USB_CRH 0x88811888 /* PA15...PA8 */

15

16#define VAL_GPIO_OTHER_ODR VAL_GPIO_USB_ODR

17#define VAL_GPIO_OTHER_CRL VAL_GPIO_USB_CRL

18#define VAL_GPIO_OTHER_CRH VAL_GPIO_USB_CRH

19

20#define VAL_GPIO_LED_ODR 0xFFFFFFFF

21#define VAL_GPIO_LED_CRL 0x88888888 /* PC7...PC0 */

22#define VAL_GPIO_LED_CRH 0x88388888 /* PC15...PC8 */

The button will still not work with this code I still had to add it the gnuk / chopstx source code. First I need to add a new function in chopstx to wait until the button has been pressed. I set it up to blink the led every 100ms and break out of the loop if the button goes high (I have a 10k pull down resistor on the button)

1void wait_button() {

2 #if defined(GPIO_BUTTON_PIN)

3 while (1){

4 set_led(1);

5 wait(1000000);

6 if( (GPIO_OTHER->IDR & (1 << GPIO_BUTTON_PIN)) ) break;

7

8 set_led(0);

9 wait(1000000);

10 if( (GPIO_OTHER->IDR & (1 << GPIO_BUTTON_PIN)) ) break;

11 }

12 #endif

13}

Next I added the wait button function in the openpgp.c file at line 936 and 1144

#ifdef CONFIRM_BUTTON_SUPPORT

wait_button();

#endif

(https://github.com/TheStaticTurtle/gnuk/search?q=wait_button&unscoped_q=wait_button)

and added the CONFIRM_BUTTON_SUPPORT option to the command line arguments (https://github.com/TheStaticTurtle/gnuk/search?q=CONFIRM_BUTTON_SUPPORT&unscoped_q=CONFIRM_BUTTON_SUPPORT)

Since I didn't have any experience programming and stm32 outside the Arduino environment I followed danman guide to build and transfer the program.

I started by creating a config for OpenOCD (Debugger / Programmer) and setting up to use a st link V2 to flash the software.

#daemon configuration

telnet_port 4444

gdb_port 3333

#interface

interface hla

hla_layout stlink

hla_device_desc "ST-LINK/V2"

hla_vid_pid 0x0483 0x3748

#transport select swd

# The chip has 64KB sram

set WORKAREASIZE 0x10000

source [find target/stm32f1x.cfg]

#adapter_khz 100

gdb_breakpoint_override hard

OpenOCD open a telnet server on port 4444 that you can use to send commands to it. I, next wrote a build and flash script to simplify my life during testing, since I change the source code on a different computer that the one I used to flash (Windows/Linux), I added git pull to make sure that I'm up to date with my GitHub

Build script:

cd gnuk

git pull

git submodule update --init

git submodule sync

git submodule update --remote

cd chopstx

git pull origin master

cd ..

cd src

./configure --vidpid=234b:0000 --target=TURTLE_AUTH --enable-confirm-button

make clean

make

Flash script (Not the best but it works):

echo 'stm32f1x unlock 0' > tmp.network

echo 'reset halt' >> tmp.network

echo 'stm32f1x unlock 0' >> tmp.network

echo 'reset halt' >> tmp.network

echo 'flash erase_sector 0 0 127' >> tmp.network

echo 'flash write_bank 0 ./gnuk/src/build/gnuk.bin 0' >> tmp.network

echo 'reset' >> tmp.network

echo 'exit' >> tmp.network

cat tmp.network | netcat 127.0.0.1 4444

rm tmp.network

So after flashing sucess the device show up in dmseg

[ 808.561960] usb 2-1: Product: Gnuk Token

[ 808.561964] usb 2-1: Manufacturer: Free Software Initiative of Japan

[ 808.561967] usb 2-1: SerialNumber: TURTLE-1.2.15-87033357

After executing gpg --card-status I was greeted by a wonderful output that told me that everything was working correctly

$ gpg --card-status

Reader ...........: 234B:0000:TURTLE-1.2.15-87033357:0

Application ID ...: D276000124010200FFFE870333570000

Version ..........: 2.0

Manufacturer .....: unmanaged S/N range

Serial number ....: 87033357

Name of cardholder: [not set]

Language prefs ...: [not set]

Sex ..............: unspecified

URL of public key : [not set]

Login data .......: [not set]

Signature PIN ....: forced

Key attributes ...: rsa2048 rsa2048 rsa2048

Max. PIN lengths .: 127 127 127

PIN retry counter : 3 3 3

Signature counter : 0

Signature key ....: [none]

Encryption key....: [none]

Authentication key: [none]

General key info..: [none]

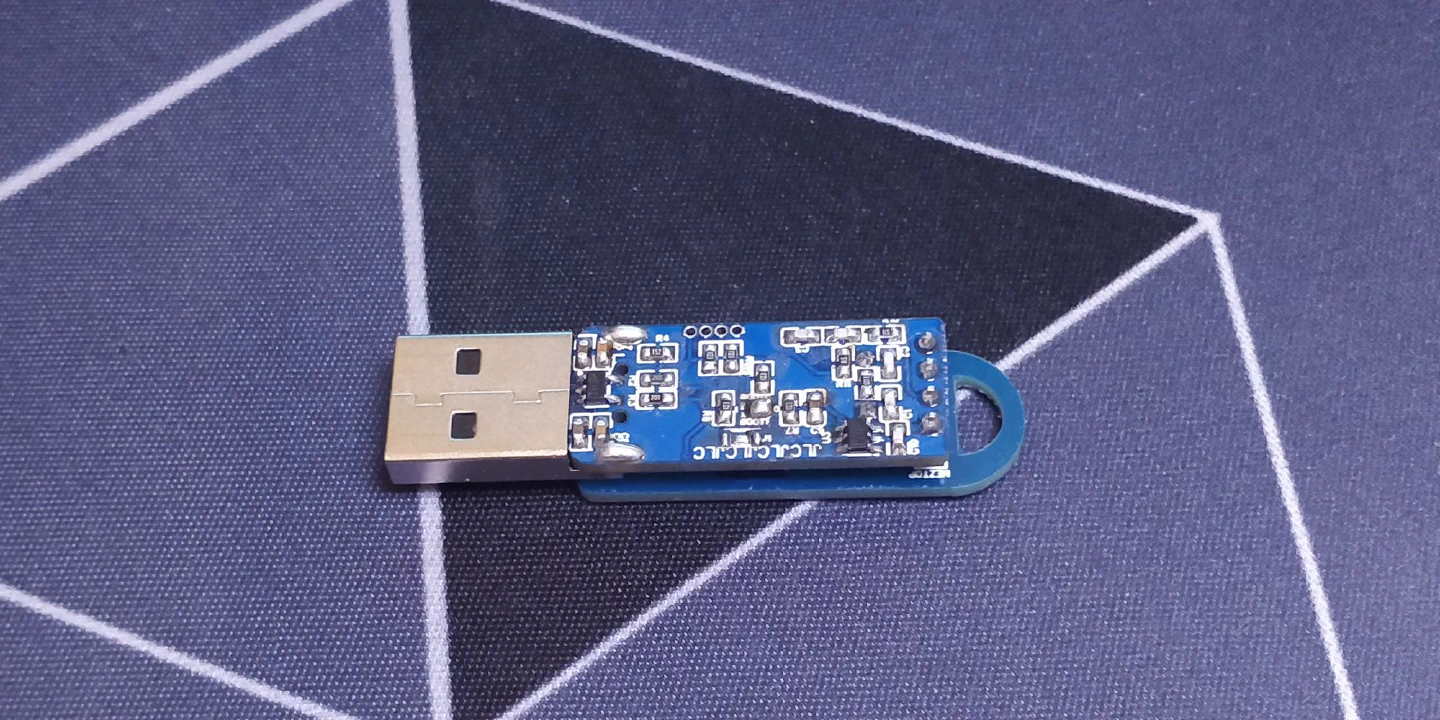

After that I could use it like a normal gpg smart card. However, this mess isn't superb to carry around and very fragile:

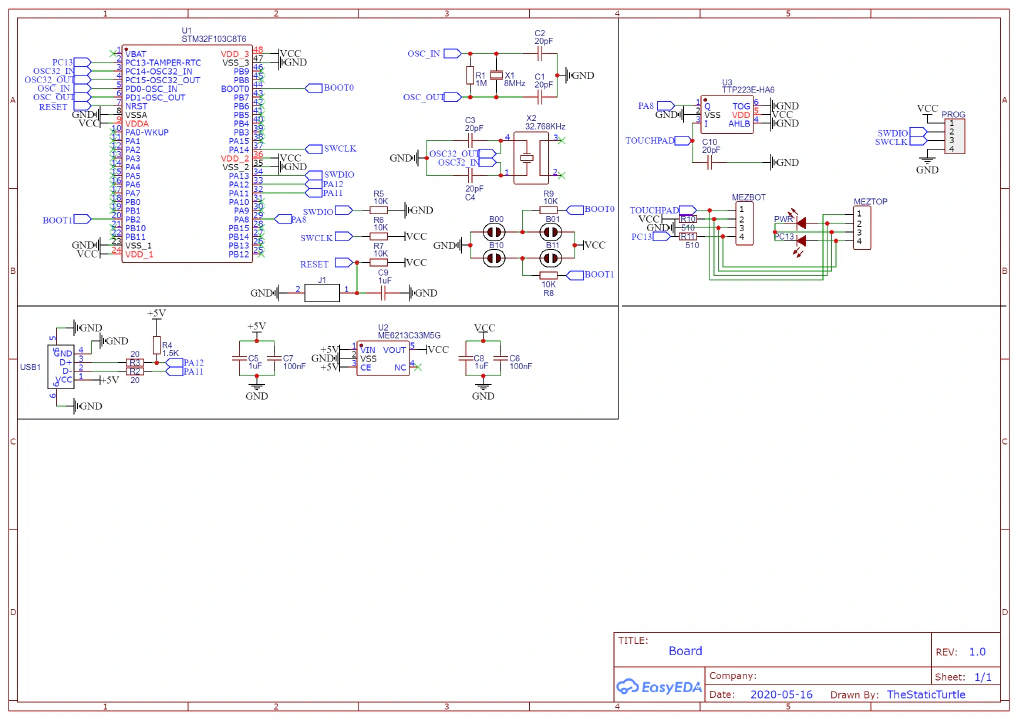

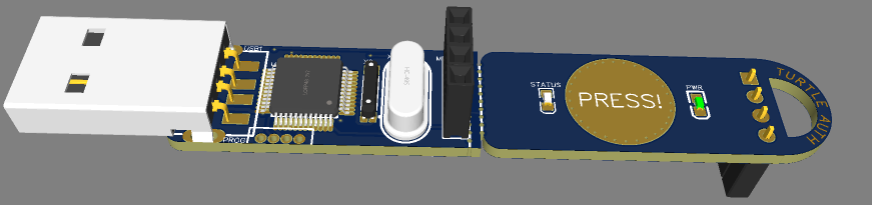

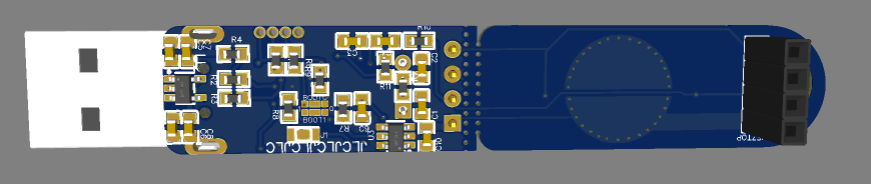

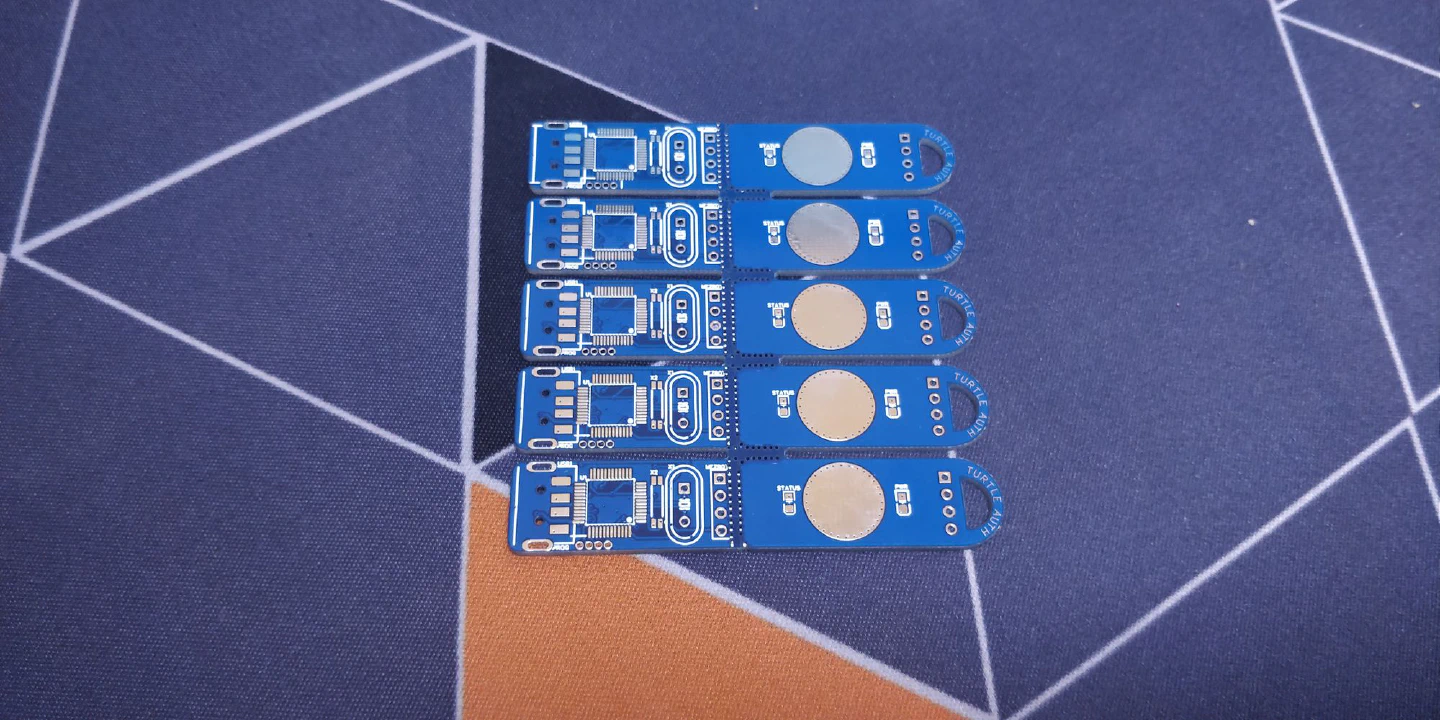

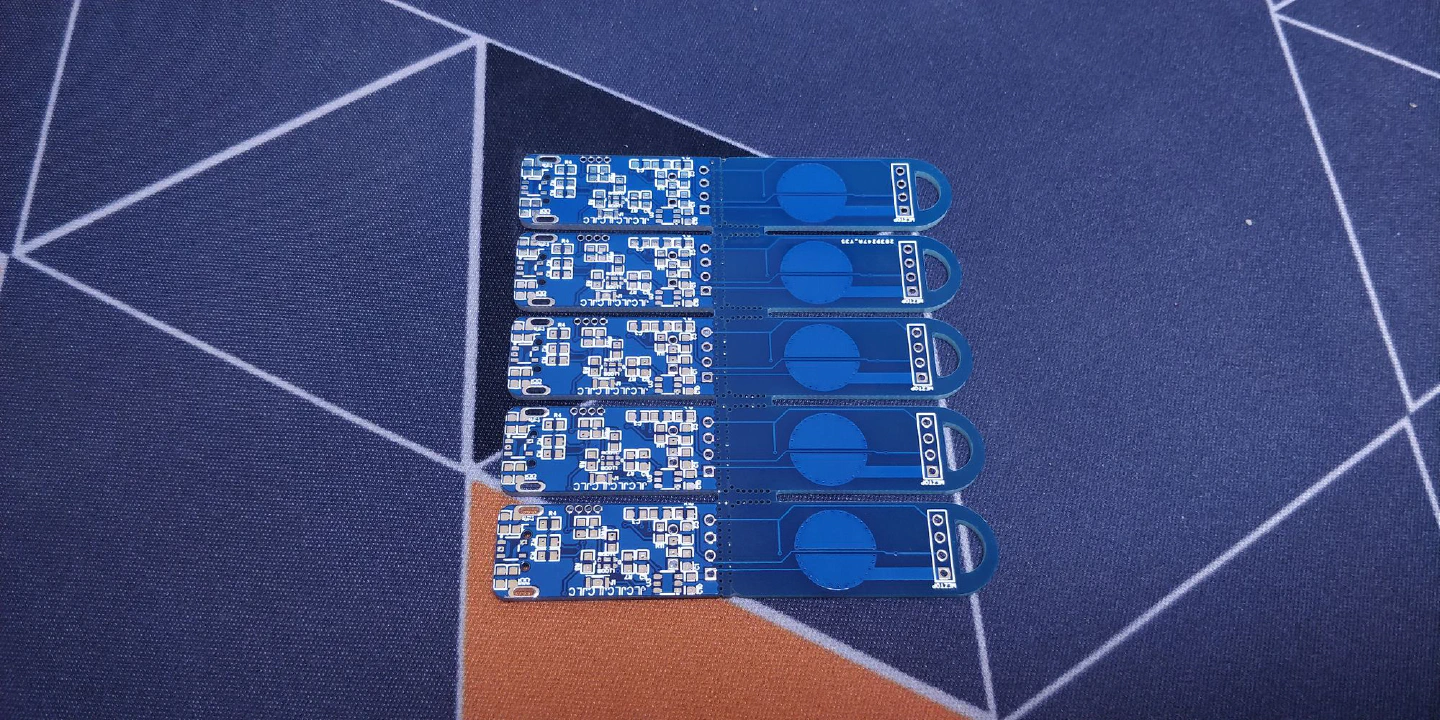

So I decided to improve my by design and soldering skill by only choosing 0603 sized components (Which is retrospect a size that I won't go further unless I get a magnifying glass or a microscope).

I wanted to have to boards one on top of each other to clean up the design and make it appear less "hacky" and I recently discovered the TTP223E Touch control ic, so I don't wanted to use a typical pushbutton to validate the access. So I basically cloned the blue pill design and added the ic:

Want to chat about this article? Just post a message down here. Chat is powered by giscus and all discussions can be found here: TheStaticTurtle/blog-comments